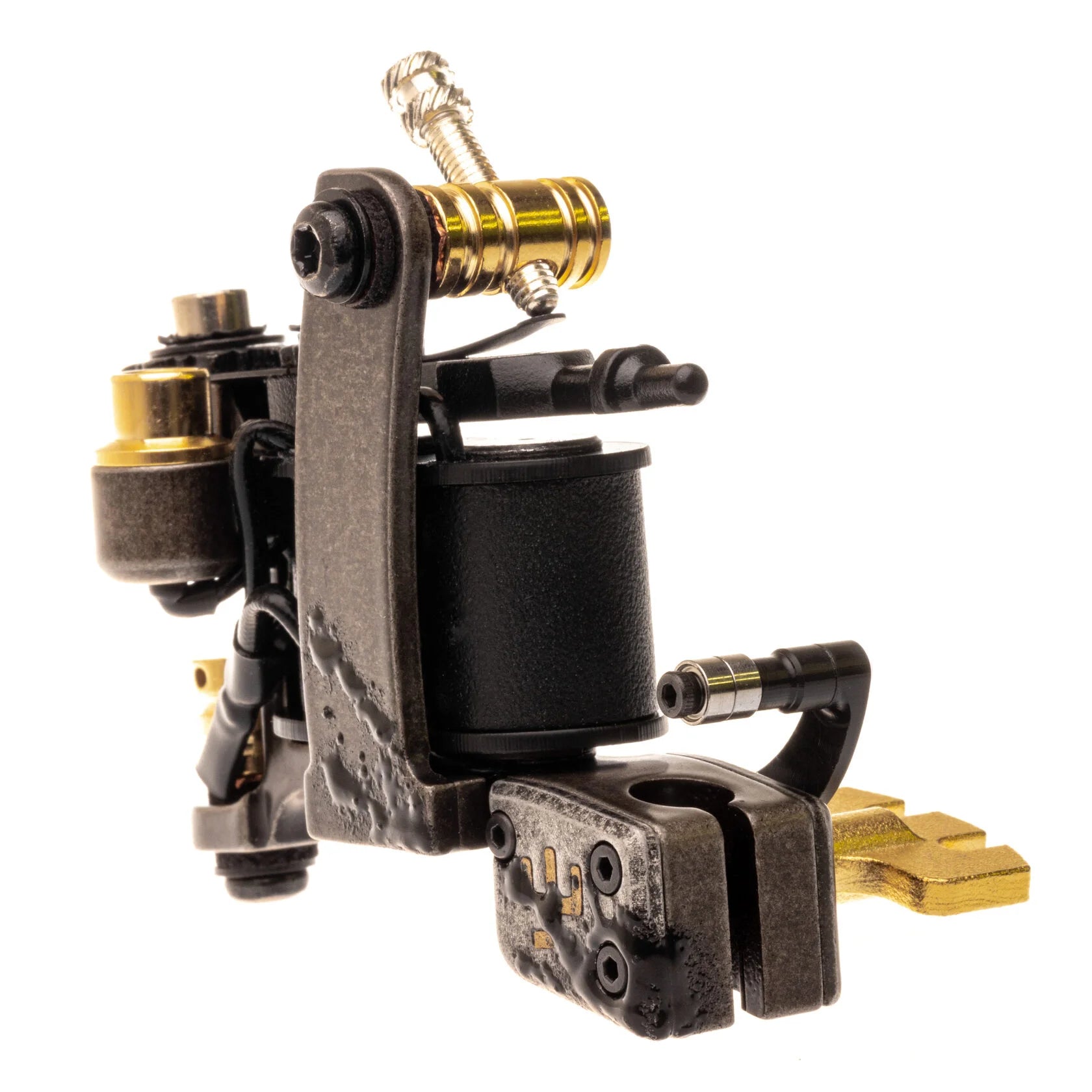

VLAD BLAD - Coil - Fine Liner Pro - Old Petroleum

Couldn't load pickup availability

Features:

· Premium steel frame optimal for vibration damping weighing 212g

· Built-in RCA connector

· Fantastic SuperJaws tube vise that doesn't break plastic backstems

· Needle stabilizer (No need to use rubber bands)

· Fast and solid black/color packing with 7-25+M

· Sharp and controlled hit without blowouts

· Amazing skin feedback for full control

· Non-traumatic

· Longlife Monospring

· 25 year warranty for the first owner

· Made with care for the environment

Fine Liner

Looking for a liner that can handle from fine to medium lines? Meet the Fine Liner - the next generation of liner machines that's sure to blow your mind.

We've taken 15 years of experience building the best coil tattoo machines around and poured it all into this bad boy. And let me tell you, it shows. With the Fine Liner, you can work with 3RL up to 9RL needles like a pro, delivering an absolutely killer hit that's sharp and powerful, yet totally under control.

That means you can whip out crisp, one-pass lines without any fear of blowouts or wobbly edges - even with the finest needles. And when you crank up the voltage, this baby kicks into high gear, nailing 9RL lines like it's nothing.

It's like having two machines in one - a Fine Liner and a Regular Lliner - all wrapped up in a perfectly balanced frame with 9+7 wrap coils and a lightweight armature bar. This machine is built to deliver fast, clean, and consistent lines that won't let you down. The lines don't come out broken, weak, or blown out.

So if you're looking for a liner that can handle precision fine lines you throw at it, the Fine Liner is the way to go. Trust us, you won't regret it.

Our coils are several times faster than almost all rotaries when used on areas such as the abdomen, buttocks, hands and knees. No need to press down on the needle and stretch the skin too much. With our coils, you simply touch the skin and quickly pull a line of any thickness. This is simply essential for some styles.

Many famous Line Work, Geometry, and Blackwork tattoo artists work with these machines and consider them the best. In recent years, a multitude of artists working in these styles have switched to rotaries. However, only a negligible portion of them have learned to make their lines with a rotary as high-quality as those made with coils.

You can tune the coils to hit exactly how you need them to, by making small adjustments that make a big impact on your tattoos. Don't settle for less, choose our legendary coils for your tattooing needs.

Factory pre-tuned

Are you tired of spending hours trying to get your coil machine just right? With our coils, you won't have to worry about that anymore. Our machines are already perfectly tuned right out of the box, so you can get right to work without any fuss.

We take quality seriously, which is why every coil undergoes three rigorous quality checks before leaving our factory. Our machines are built to last, with precisely crafted angles on the frame that give the springs the perfect curve. You won't have to worry about bending the springs to get the right tuning - simply adjust the contact screw and you're good to go.

Save yourself time and frustration with our factory-tuned coils. Trust us, you won't want to use anything else once you've experienced the convenience and precision of our machines.

Highest reliability

Are you tired of constantly having to replace your tattoo machine springs? Are you tired of constantly worrying about your machine breaking down mid-tattoo? Look no further than our Longlife Monospring in our coils.

We've developed our own proprietary technology for creating almost indestructible springs. Unlike other companies that use regular spring steel, we use high-quality steel meant for musical instruments, which costs several times more. Plus, while other companies use mechanical cutting and stamping, which creates micro-cracks in the metal that can lead to breakage, we use precision wire EDM cutting without the risk of overheating or damaging the springs.

After the bending process, our springs undergo a stress-relieving treatment to further strengthen the metal structure.

We still see our coils from 2007 in regular use today. That's why we offer a 25-year warranty for the first owner. Don't settle for less than the best. Choose our coils for the highest level of reliability and peace of mind.

Environmental responsibility

A huge amount of carbon is released during steel production. We use three times less steel than in traditional milling from a solid piece. We also use a grade of steel made from partially recycled material. This is possible due to the use of

electro-erosive cutting followed by welding of the frame parts. You get a durable steel frame with a significantly smaller carbon footprint.

We have thrown all unnecessary things from the box and simplified the packaging because what matters most is what's inside.

P.S.

Our coils have long been a legend. Several generations of artists

have grown up on them. We have produced tens of thousands of coil machines sold

all over the world since 2007 and we know how to make them well.

Sincerely, Vlad Blad